What Is The Time Of The Slowest Workstation In A Production System

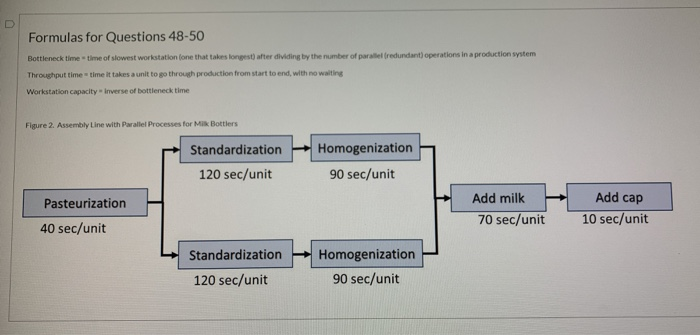

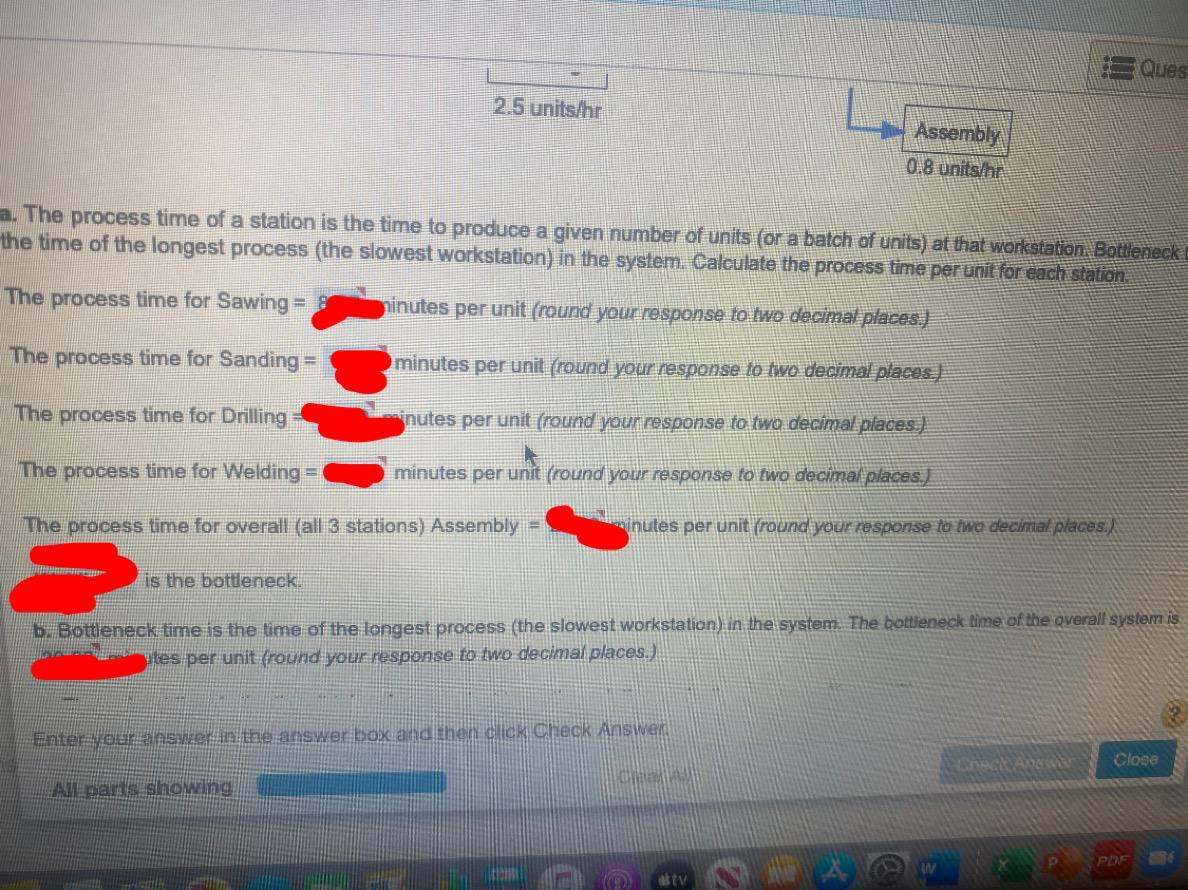

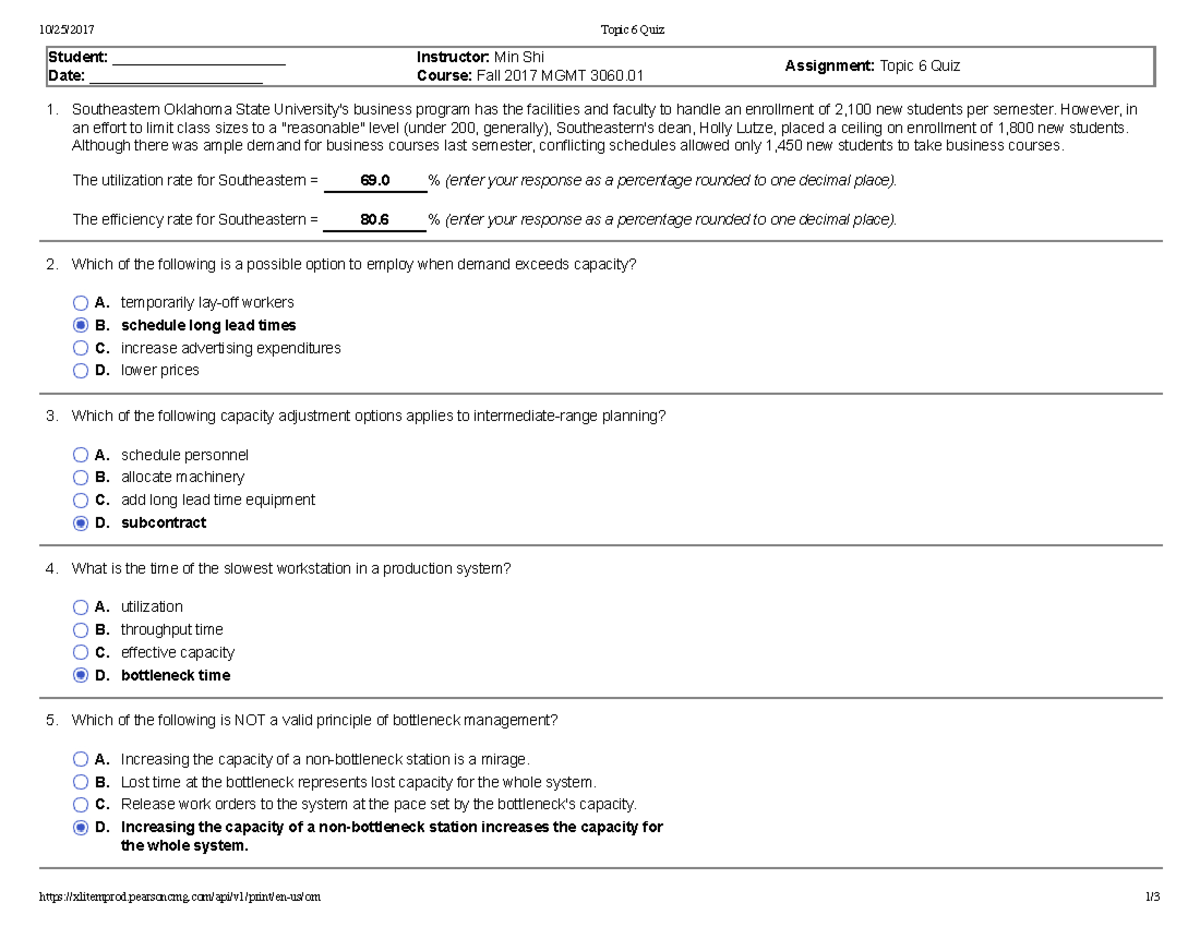

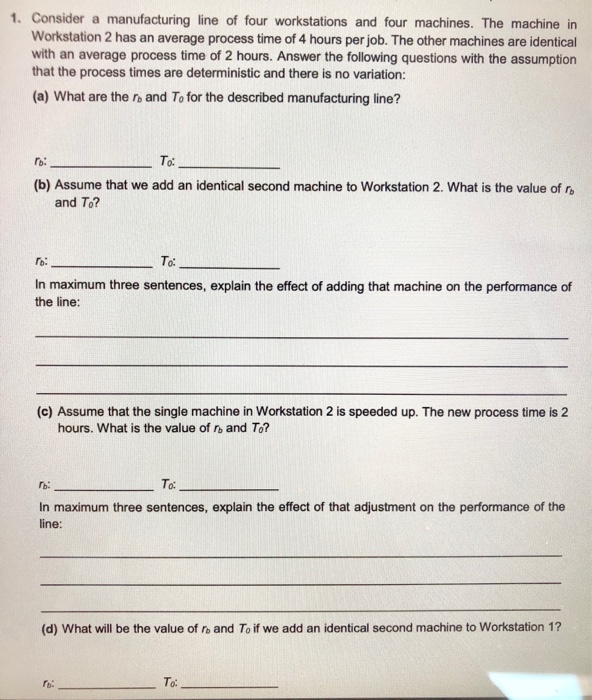

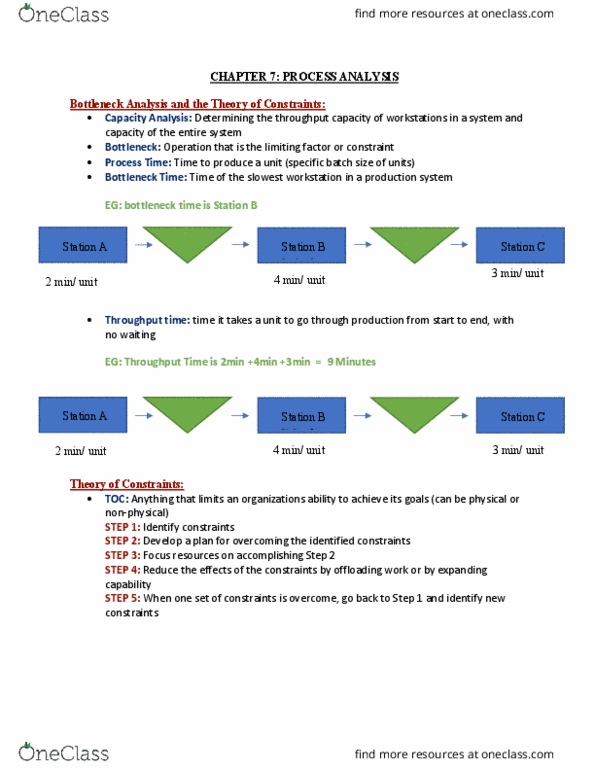

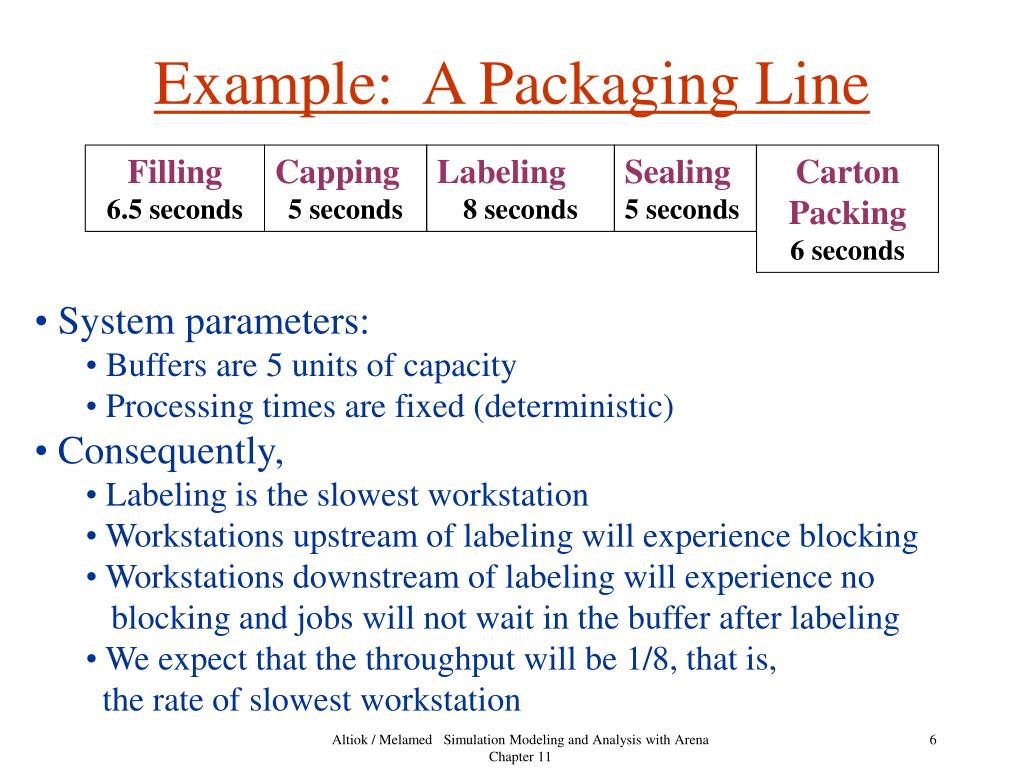

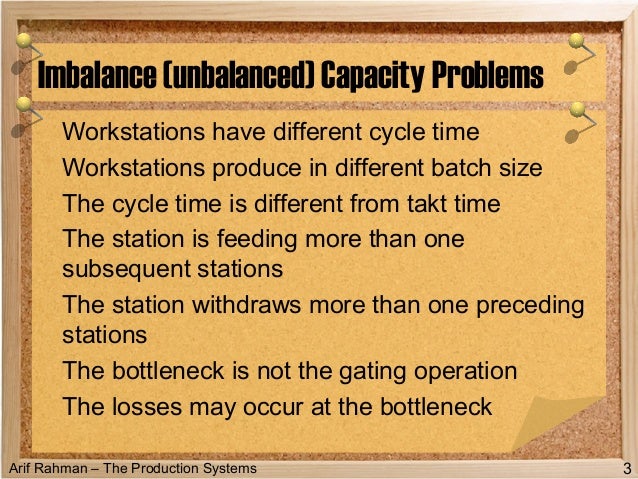

What is the time of the slowest workstation in a production system. 1Release work orders to the system at the pace of set by the bottlenecks capacity 2Lost time at the bottleneck represents lost capacity for the whole system 3Increasing the capacity of a non-bottleneck station is a mirage 4Increasing the capacity of a bottleneck increases the capacity of the whole system. Each workstation processes unit at its own rate. Focus resources on accomplishing step 2 Step 4.

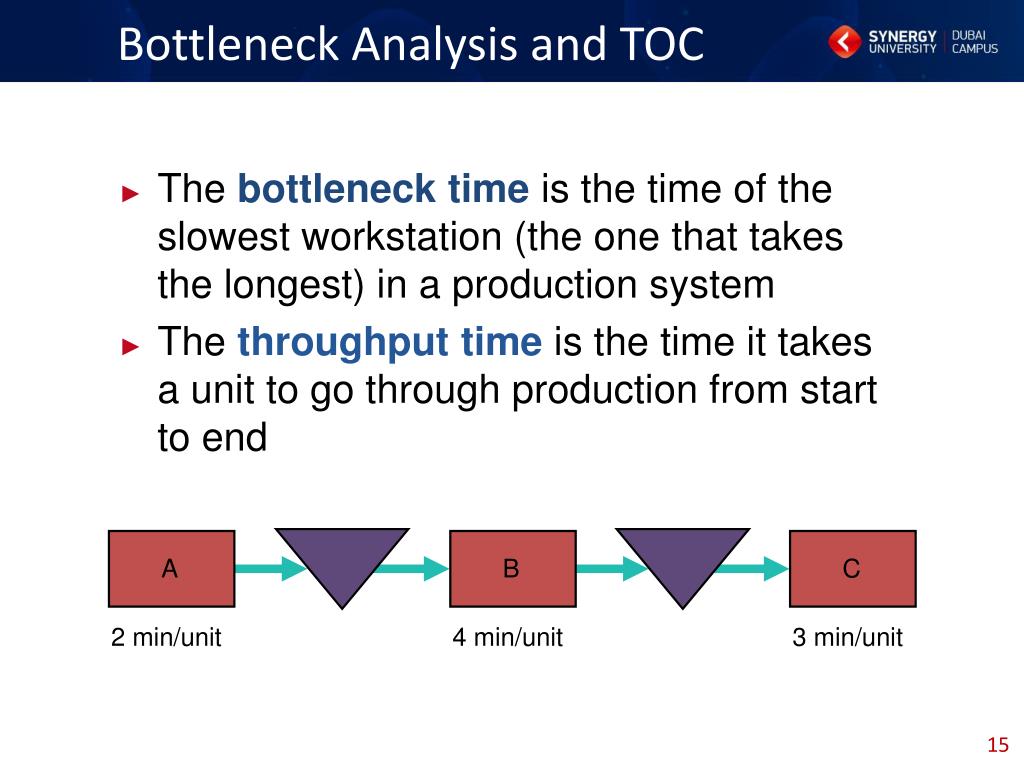

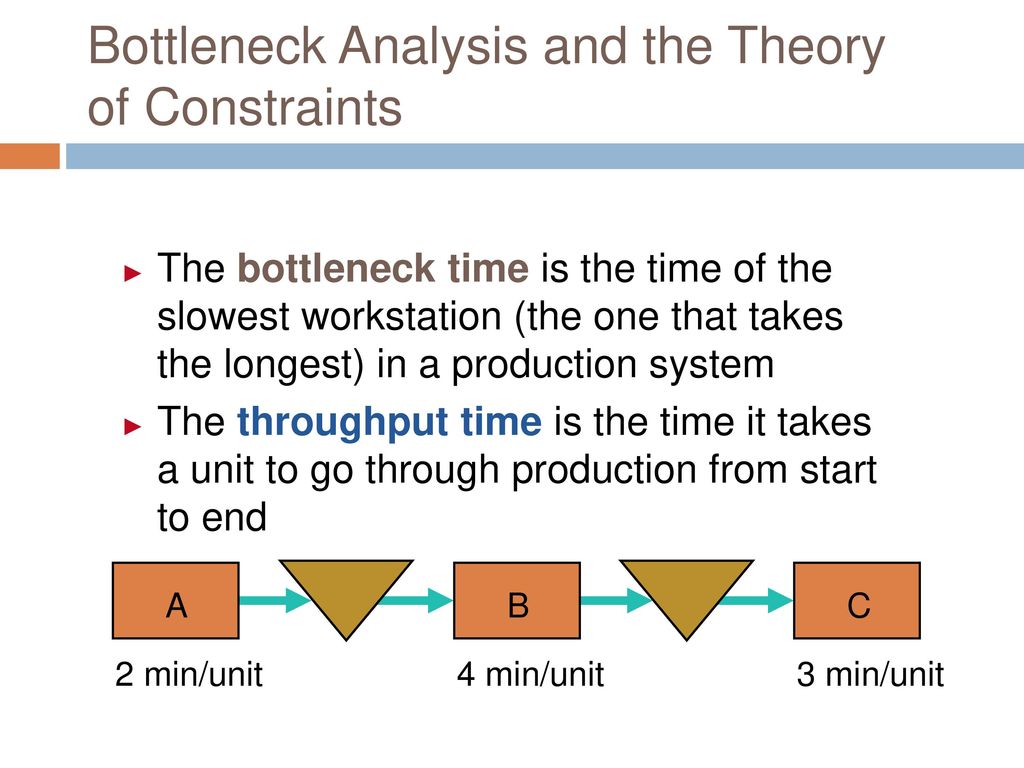

Aeffective capacity Butilization Cthroughput time Dbottleneck time. The time it takes a unit to go through production from start to end. How to identify the bottleneck.

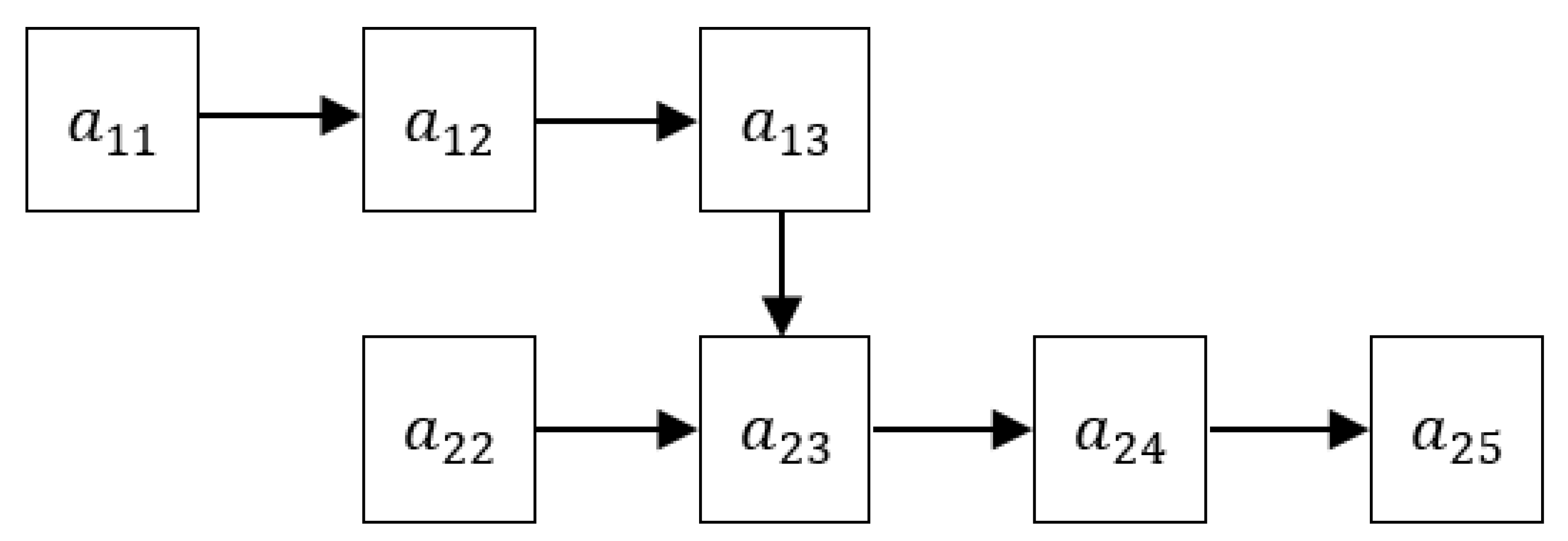

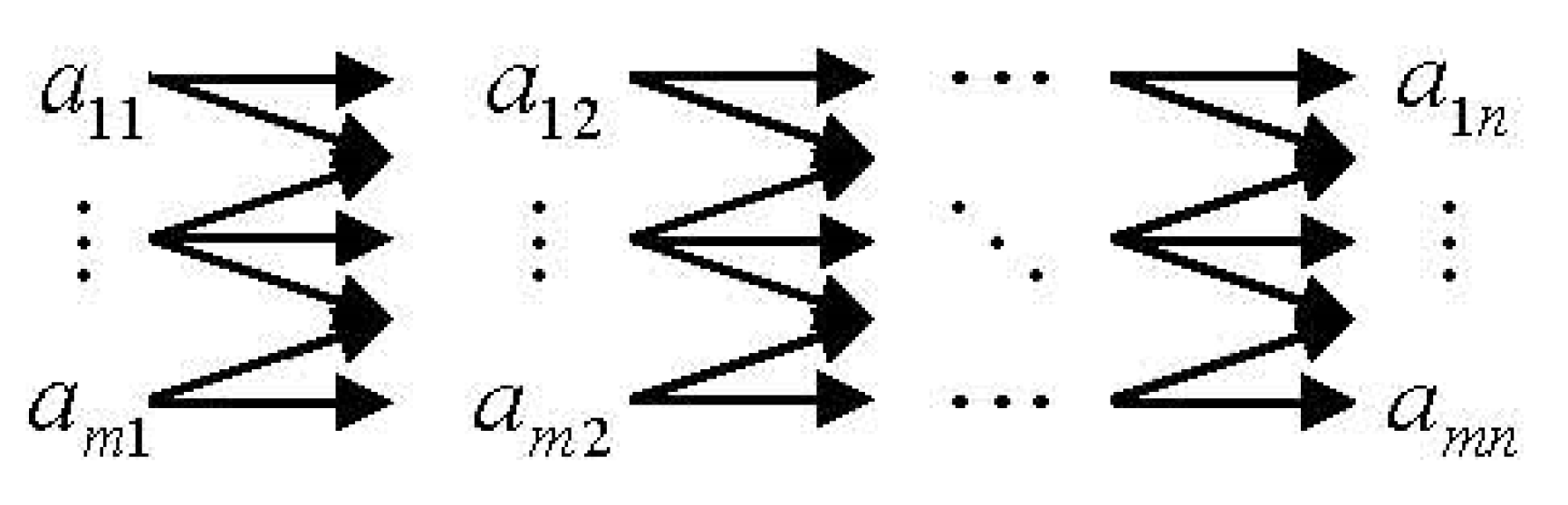

The bottleneck station is the slowest workstation in a production line and therefore it limits the pace of the entire line. Automated Production Lines Simple problems on Geneva mechanism 3 A Geneva with six slots is used to operate the worktable of a dial- indexing machine. Cycle Time The time it takes one workstation in a process to complete its workload for processing a part.

Proximity privacy and permission. On the line and we can expect the production to flow smoothly. Effective capacity O c.

Is the time of the slowest workstation the one that takes the longest in a production system throughput time. The objective of warehouse layout is to. What is the time of the slowest workstation in a production system.

Once overcome go back to Step 1 and find new constraints. What is the time of the slowest workstation in a production system. What is the time of the slowest workstation in a.

What is the time of the slowest workstation in a production system. This takes 8 hours.

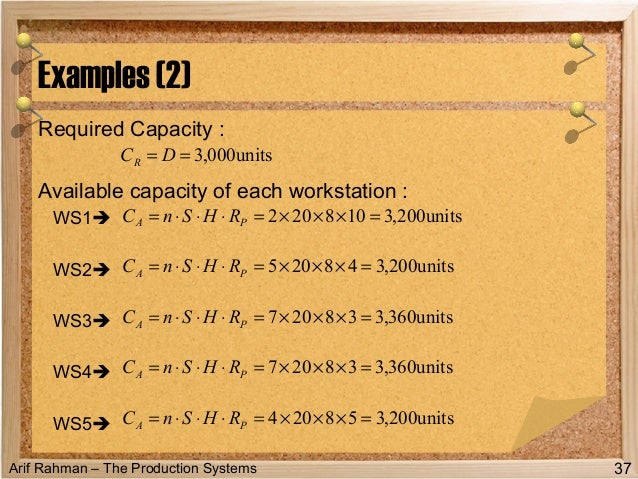

33 What is production capacity.

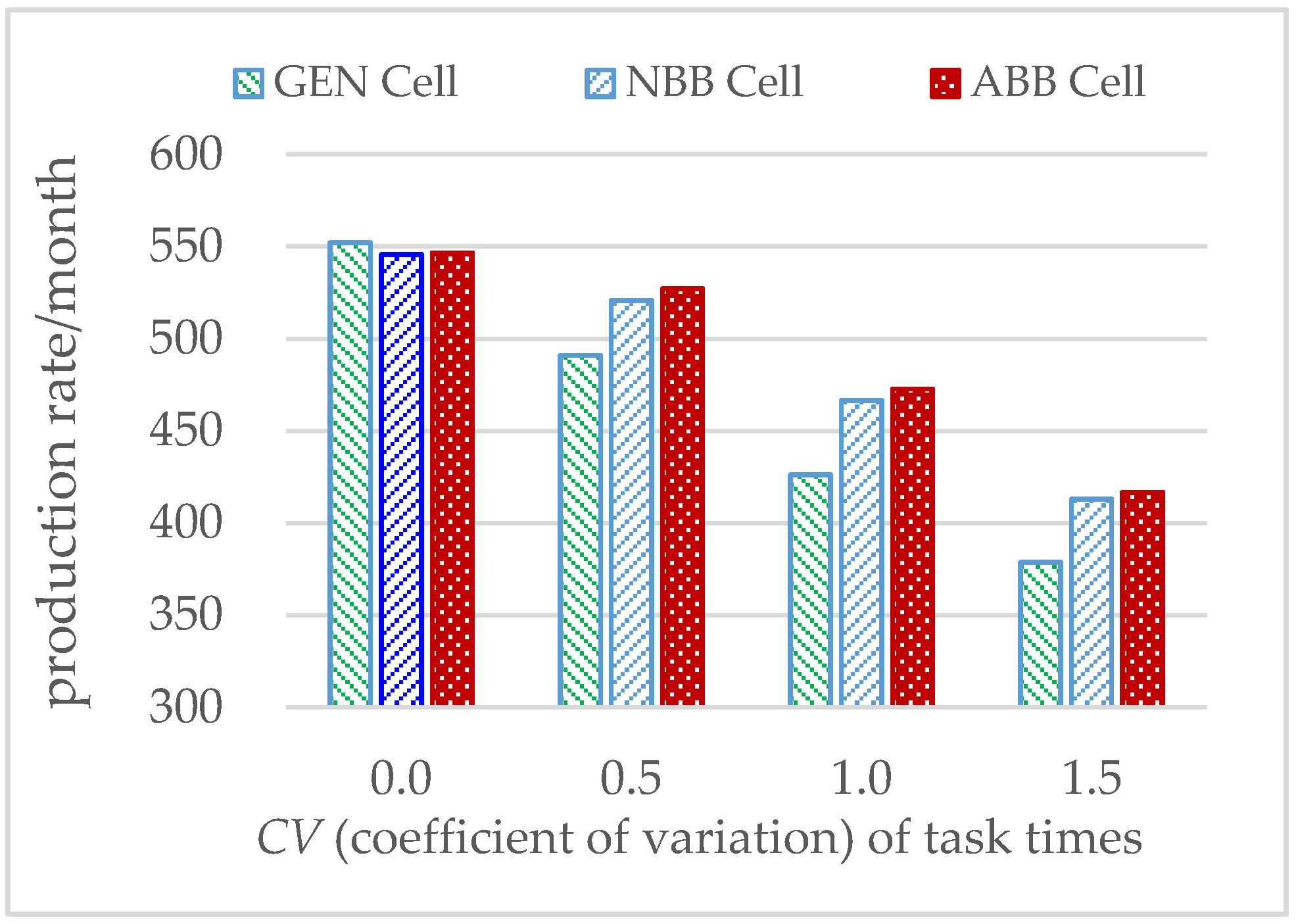

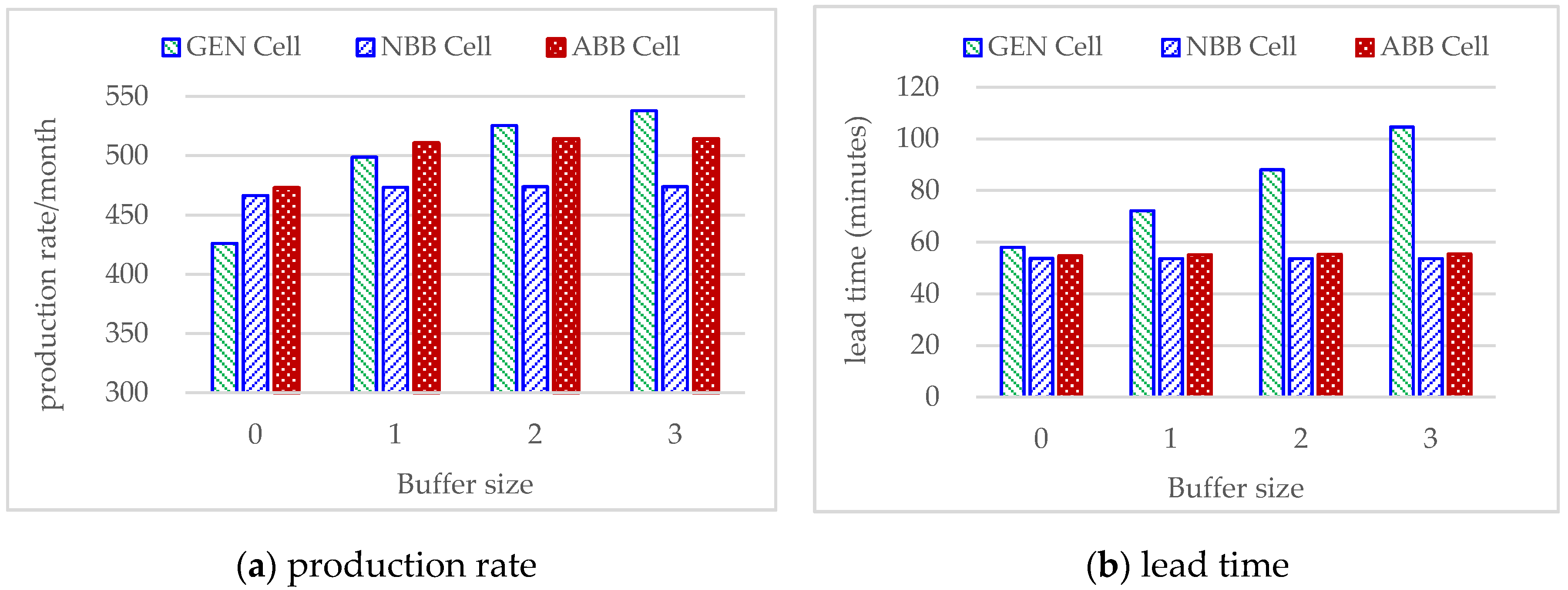

Capacity planning involves long-term and short- term considerations. Automated Production Lines Simple problems on Geneva mechanism 3 A Geneva with six slots is used to operate the worktable of a dial- indexing machine. Cycle time is decided by performance of the slowest machine. Proximity privacy and permission. Workspace can inspire informal and productive encounters if it balances three physical and social aspects. This concept is an integral part of inventory management and hence is used in inventory management techniques like JIT or Just in time and also other conventional stock control. Cycle Time is not the same as Lead Time TaktTime Takttime Net Available Time per Day Customer Demand. Commonly referred to as a bottleneck the constraint equipment is generally easy to identify. What is the time of the slowest workstation in a production system.

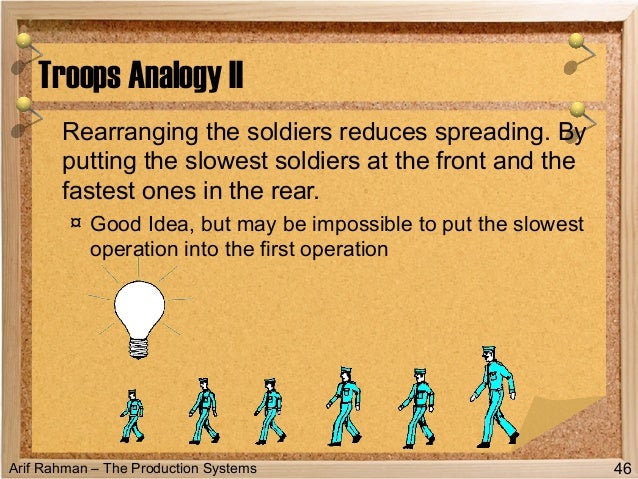

In most practical situations it is very difficult to achieve perfect balance. Bottleneck time What is the major difference in focus between a location decision in the service sector vs. When in a single facility of production the subsystem is coupled it means the speed of operation of the entire system is constrained by the slowest workstation. On the line and we can expect the production to flow smoothly. How to identify the bottleneck. Theory of Constraints Step 1. The objective of warehouse layout is to.

Post a Comment for "What Is The Time Of The Slowest Workstation In A Production System"